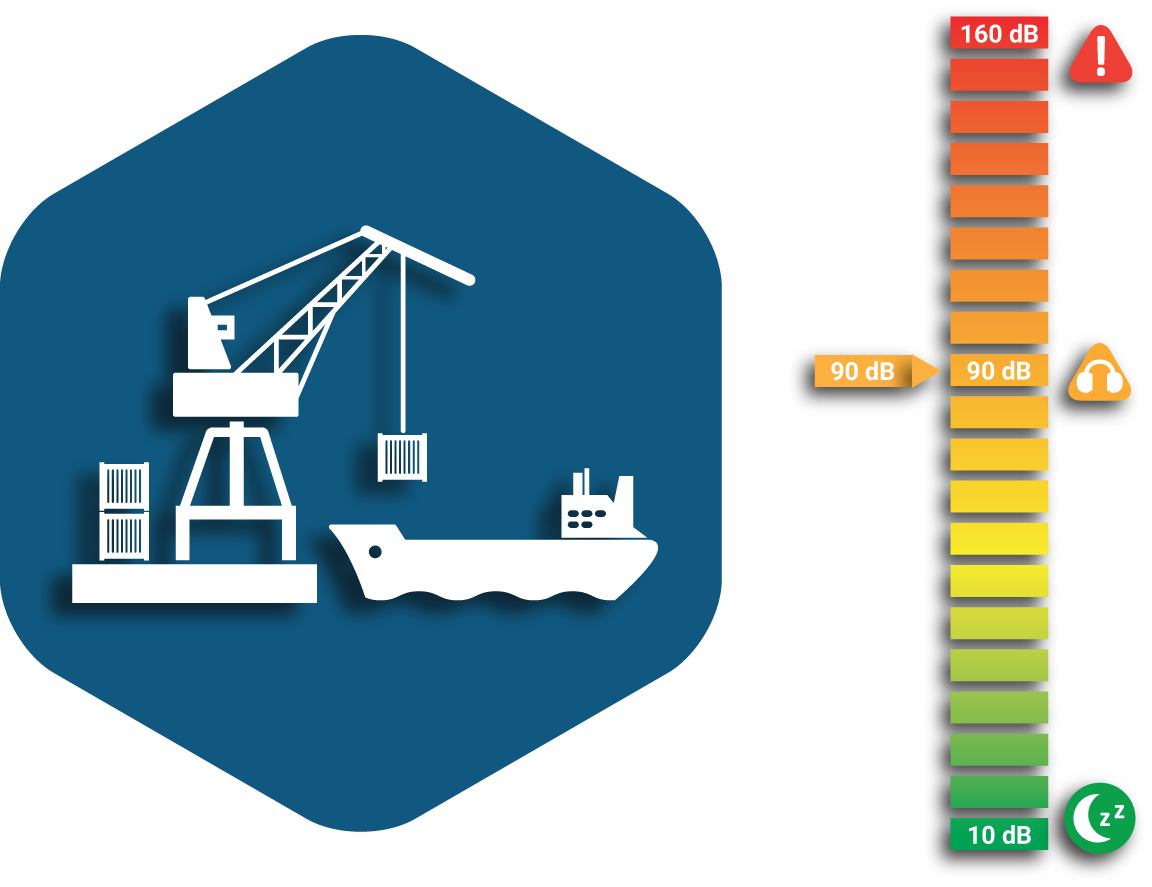

Harbour and Ship Noise

Average LEQ: 90 dB(A)

harbour type: cargo and passengers

distance from the observer: ?25m

Noise coming from harbors where unloading and loading of containers take place can be very disturbing. Cargo harbors as well as passenger harbors typically host a variety of noise sources: moving vehicle and machineries, ship engines and signaling systems (e.g., horns, sirens, whistles) are just some examples.

Generally speaking, a direct correlation between the dead weight tonnage (DWT) of a ship and her sound power level can be established. Moreover, smaller ships have high-speed engines with higher frequency content in noise and smaller ventilation systems.

Vessel-generated noise has its most significant component in the engine: the noise can travel both via the atmosphere and through the structure of the craft and even through water. The amplitude of the perceived noise depends on the size, the design and the location of the engine, as well as the craft size and construction type.

More in details, the diesel generator on board the vessel is the prevailing noise source during port stay phases, when it radiates from the ship exhaust to the surrounding environment. This is mainly due to the position of the diesel engine exhaust, which is normally placed on top of the ship’s funnel(s), thus occupying a higher position than the majority of the surrounding structures. In such case, the sound can propagate almost freely over larger distances since no sound reflection or absorption mechanisms from the surrounding buildings and environments may occur. Therefore properly designed silencer and mufflers are needed.

Another source of noise from ships is represented by their ventilation systems: room ventilation, cargo ventilation, AC-systems, galley ventilation, etc. In addition, secondary noise sources are also present: hydraulic pumps, winches, cooling container systems, on-board cranes, signaling systems.

Shipping and unshipping operations, moreover, involve a series of equipment and machineries in order to move properly containers and materials from the ships and all across the harbor. Dock cranes and straddle carriers, loaders, fork-lifts, trucks, tractors and railcars are the most common noise sources in such a scenario.

As a reference, we can consider the following SPL average values:

Generally speaking, a direct correlation between the dead weight tonnage (DWT) of a ship and her sound power level can be established. Moreover, smaller ships have high-speed engines with higher frequency content in noise and smaller ventilation systems.

Vessel-generated noise has its most significant component in the engine: the noise can travel both via the atmosphere and through the structure of the craft and even through water. The amplitude of the perceived noise depends on the size, the design and the location of the engine, as well as the craft size and construction type.

More in details, the diesel generator on board the vessel is the prevailing noise source during port stay phases, when it radiates from the ship exhaust to the surrounding environment. This is mainly due to the position of the diesel engine exhaust, which is normally placed on top of the ship’s funnel(s), thus occupying a higher position than the majority of the surrounding structures. In such case, the sound can propagate almost freely over larger distances since no sound reflection or absorption mechanisms from the surrounding buildings and environments may occur. Therefore properly designed silencer and mufflers are needed.

Another source of noise from ships is represented by their ventilation systems: room ventilation, cargo ventilation, AC-systems, galley ventilation, etc. In addition, secondary noise sources are also present: hydraulic pumps, winches, cooling container systems, on-board cranes, signaling systems.

Shipping and unshipping operations, moreover, involve a series of equipment and machineries in order to move properly containers and materials from the ships and all across the harbor. Dock cranes and straddle carriers, loaders, fork-lifts, trucks, tractors and railcars are the most common noise sources in such a scenario.

As a reference, we can consider the following SPL average values:

- Diesel engine exhaust (on board, within the engine room, 15m from the observer): 135 dB(A)

- Diesel engine room fan, volume flow of 120000m3/h (on board, within the ventilation room, 15m from the observer): 110 dB(A)

- Diesel engine room fan, volume flow of 15000m3/h (on board, within the ventilation room, 15m from the observer): 100 dB(A)

- Diesel engine room fan, volume flow of 1000m3/h (on board, within the ventilation room, 15m from the observer): 80 dB(A)

- Container cooling system (15m from the observer on ground): 90 dB(A)

- Fishing vessel (25m), port stay (15m from the observer on the ground): 65 dB(A)

- Fishing vessel (25m), port stay (25m from the observer on the ground): 62 dB(A)

- Multi-purpose container vessel (100m), port stay (15m from the observer on the ground): 80 dB(A)

- Multi-purpose container vessel (100m), port stay (25m from the observer on the ground): 68 dB(A)

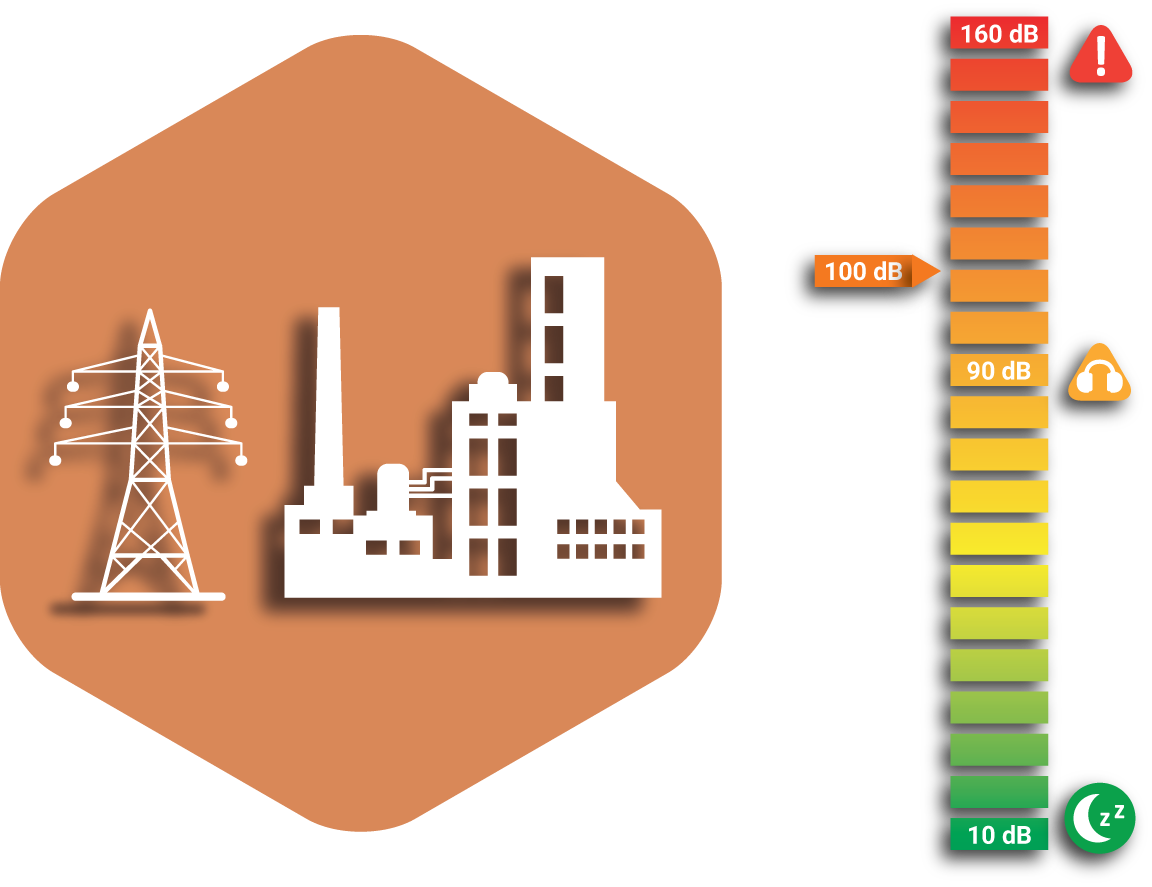

Industrial Noise

Average SPL: 110 dB(A)

Generic plant

distance from the observer: ?15m

The noise caused by an industrial plant (or by a part of an industrial plant) and perceived in a surrounding residential area is not easily measurable, since it cannot be easily separable from the other sources (e.g., other plants, traffic, etc.) due to the distance between the plant itself and the residential area.

However, this kind of noise is determined by a series of industrial machineries and equipment, such as: rotating electrical machines, transformers, rotors and stators, combustion engines, compressors, electrical switch gears, ventilation fans, vibrating panels, HVAC systems, office machines, turbines, hydraulic and pneumatic tools and pumps.

When monitoring industrial noise, the operations performed by the plant equipment must be taken into account as well, since they generate different noise levels. The most typical operations depend on the kind of plant. Amongst them (and in addition to the ones enlisted above) we can mention: presses, forges, sand-blasters, furnaces, boilers, metal cutters/formers/dividers, punchers, shearers, milling machines, grinders, textile machines, printing machines, filling machines, robotic arms, conveying belts and lanes.

It is worth to say that industrial noise is a primary concern for professional workers, who have to work close to industrial equipment for a significant number of hours per day, but its effects impact also on the surrounding residential areas, especially when they are in close proximity to a plant.

As a reference, we can consider the following LEQ average values at 5m from the observer, if not specified differently, depending on the different industrial sectors (source: Health and Safety Executive, Topic Inspection Pack – Noise, HSE, May 2008):

However, this kind of noise is determined by a series of industrial machineries and equipment, such as: rotating electrical machines, transformers, rotors and stators, combustion engines, compressors, electrical switch gears, ventilation fans, vibrating panels, HVAC systems, office machines, turbines, hydraulic and pneumatic tools and pumps.

When monitoring industrial noise, the operations performed by the plant equipment must be taken into account as well, since they generate different noise levels. The most typical operations depend on the kind of plant. Amongst them (and in addition to the ones enlisted above) we can mention: presses, forges, sand-blasters, furnaces, boilers, metal cutters/formers/dividers, punchers, shearers, milling machines, grinders, textile machines, printing machines, filling machines, robotic arms, conveying belts and lanes.

It is worth to say that industrial noise is a primary concern for professional workers, who have to work close to industrial equipment for a significant number of hours per day, but its effects impact also on the surrounding residential areas, especially when they are in close proximity to a plant.

As a reference, we can consider the following LEQ average values at 5m from the observer, if not specified differently, depending on the different industrial sectors (source: Health and Safety Executive, Topic Inspection Pack – Noise, HSE, May 2008):

PLASTICS

- Size reduction machines (e.g., granulators, shredders, crumbers, etc.): 90 dB(A)

- Injection moulding machines: 95-100 dB(A)

- Extruders: 90 dB(A)

- Mould cleaning guns: 105 dB(A)

- Extrusion line cut off saws: 100 dB(A)

- Ultrasonic welding machines 95 dB(A)

WOODWORKING

- Circular saws: 95-105 dB(A)

- Moulders: 95-100 dB(A)

- Band resaws: 95-105 dB(A)

- Planer thicknessers: 97-101 dB(A)

CONCRETE

- Mould filling / demoulding / stacking on steel tables: 95-110 dB(A)

- Mould filling / demoulding / stacking on tables with rubber coverings: 86-93 dB(A)

- Vibratory presses: 70-110 dB(A)

- Rumblers / tumblers: 85-95 dB(A)

- Extrusion plants / pallet conveyors: 86-93 dB(A)

- Cleaning equipment: up to 120 dB(A)

FOOD AND DRINK

- Glass bottling: 85-100 dB(A)

- Wrapping / bagging: 85-95 dB(A)

- Bowl choppers: >90 dB(A)

- Milling operations: 85-100 dB(A)